- The following article was in the Press Democrat, the Santa Rosa newspaper on November 3rd, 2013. It is so interesting in that we went through the same issues as he did last year and came up with the same solution!

Plastic tanks catch on in wine industry

Mitch Black, owner of Black Knight Vineyards, maneuvers between plastic tanks and wooden barrels of fermenting wine while bringing a bottle of wine out for a taste at his barn in Santa Rosa. (ALVIN JORNADA/Press Democrat)

Like many winemakers, Mitch Black scrambled to find a place to store his wine last year when the largest grape crop in California history unleashed a flood of wine.

Companies that make wooden barrels and steel tanks couldn’t churn them out them fast enough to meet demand from wineries and growers, like Black, who were looking for a place to put their juice.

So Black, along with a growing number of winemakers in California, turned to plastic containers to ferment and store his valuable crop.

“I went big into Flextanks last year, because I didn’t have another option,” said Black, owner of Black Knight Vineyards.

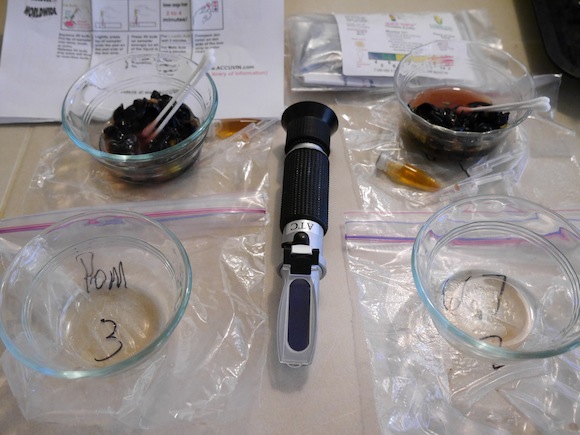

In an old barn surrounded by vineyards on his Santa Rosa property, Black keeps several plastic cylindrical barrels that he uses for his personal winemaking. A batch of pinot noir grapes ferment in a thick, blue plastic olive barrel that holds about 55 gallons of grapes and their steaming juices, while a series of 70-gallon Flextanks, made of a oxygen-permeable polyethylene, hold maturing pinot noir from the 2012 and 2013 crops.

For his commercial operation, Black has a series of larger, stackable Flextanks that hold up to 300 gallons.

Flextank, one of the main domestic manufacturers of plastic tanks for wine, has increased its sales about 20 percent a year since 2006, said Mike Humes, vice president of operations and marketing for the Athens, Ga., company.

“Once we get a foothold, our sales keep growing as people stack them up,” Humes said.

The Flextank vessels are free of BPA and phthalates, a group of chemicals that make plastic more flexible, he said.

“We thought we were doing something unique, but oh no, it’s becoming more mainstream,” said Erik Overholt, winemaker and vineyard manager atLinde Vineyards, a small winery in Cloverdale. “Many wineries are not wanting to mention it, because it doesn’t fit in with the romantic notion of wine.”

Overholt, a grower-turned-vintner like Black who began making wine when it was tough to sell grapes, now makes about 500 to 600 gallons of wine per season, he said.

When Overholt was comparing prices for plastic and stainless steel tanks, he found a steel tank that held about 150 gallons cost almost the same price as a plastic vessel that held 300 gallons.

“If you want to maximize your storage capacity and minimize your cost, obviously the plastic will be much more cost-efficient,” Overholt said.

The plastic tanks come in a range of sizes that make winemaking more manageable for small to mid-sized wineries, vintners said.

“A lot of the wineries are really gaining some acceptance in using this,” said Ron Althouse, director of sales for Tanks for Wine, which sells Flextanks. “At first it was kind of slow.”

Plastic tanks are being used by winemakers for fermenting the grapes, a process that can take several weeks depending on the varietal, and for aging wines, which can take about a year for some white wines or several years for reds. The wines are moved to bottles after they’ve spent time maturing, and can be aged further in the bottle.

After the oversized crop in 2012, when a record 266,000 tons of grapes were harvested in Sonoma County, many wineries still had juice in tanks and barrels when the 2013 crop — which many are predicting will be just as big — started to roll in.

That sent some shopping for alternatives to traditional new or used barrels, which have been more expensive since supply ran low last year.

“You used to be able to buy a used barrel from $20 to $60 depending on the conditions,” said Christopher Christensen, owner and winemaker for Healdsburg-based Bodkin Wines. “Those prices effectively doubled as barrels got snapped up over the summer. To a certain extent, barrels became cost-prohibitive.”

Christensen chose to invest in plastic containers for fermenting grapes after working in Australia, where the practice is more common, he said. He still ages wines in wood barrels, but is considering purchasing a plastic, egg-shaped vessel that can be used for fermenting and aging wines.

“I know concrete egg tanks are all the rage, but I didn’t exactly have the capital to spend on a concrete tank,” Christensen said.

Meanwhile, oak “staves,” which are wooden slats or chips that can be used to impart oaky flavors in wines aged in plastic, stainless steel or older barrels, have been growing in popularity, according to Alicia McBride, general manager of Innerstave, a Sonoma-based company that makes oak inserts from American and French wood.

The interest in alternatives to traditional oak barrels often comes from younger winemakers or those that aren’t “hung up” on wine being in a barrel, she said.

Many premium and ultra-premium wineries are using plastic tanks and oak staves, but most don’t want to talk about it, she said.

“There are a lot of winemakers that want to remain traditional, and I completely understand that,” McBride said. “There’s a certain sexiness about the barrel. You don’t really want to walk your tourists through the cellar and show them all these plastic containers around and then ask them to buy a bottle of wine.”